Building face shields, building community

Eau Claire locals join forces, provide resource for healthcare safety

Photo by SUBMITTED

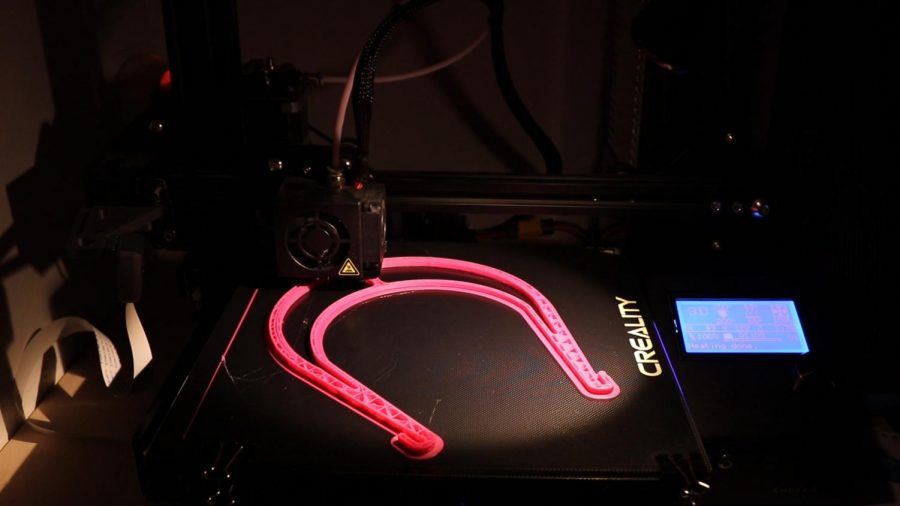

Ben Holmen and other Eau Claire volunteers possess the 3D printing resource at their own home or campus building, allowing them to make face shields in a shorter amount of time to quickly distribute.

With the unification of town locals and the help of a 3D printer, local healthcare workers now have another option of protective gear.

The healthcare industry currently faces a nationwide shortage of protective gear as workers treat those with the COVID-19 virus.

Ben Holmen, the volunteer coordinator for the Chippewa Valley Makers, said he was first inspired to help by his sister, who was in need of the benefits a face shield provides.

Holmen’s sister is employed as an emergency room nurse and continues to work while the pandemic continues, he said.

“It is knowing that I’m helping protect my sister, who is very dear to me, and doing a small thing to make her safer,” Holmen said. “Knowing she can walk into work, knowing she has that extra layer of protection that she otherwise wouldn’t have had access to.”

UW-Eau Claire has also joined in the effort to create face shield masks, as students who still live in the area are able to provide volunteer services.

Sorfina Suzali, a fourth-year material science and biology student, said she first became involved with the face shield production through a recommendation by a professor in her department.

“I decided to jump on the project,” Suzali said, “because I had read some articles about how people in the healthcare industry were scared and worried about not having enough safety gear. What I am doing is not much, but I know it is making a big impact.”

Holmen said the Makers group connected with the university through the UW-Eau Claire Material Science and Engineering Centers. Doug Dunham, the director of both centers also has collaborated with the Mayo Clinic physician staff — connecting all three areas of the community.

“(UW-Eau Claire students) have been super easy to work with and really eager to be helpful,” Holmen said. “They have students that are disinfecting and cleaning, which is super helpful. We will be doing pickups and deliveries and they are the resource for doing that.”

Holmen and other Eau Claire residents already possessed the 3D printing resource at their own home, allowing them to make face shields in a shorter amount of time for quicker distribution.

The Pablo Center at the Confluence has also made efforts to provide resources for the medical providers of Eau Claire.

According to a news release sent out April 9, the Pablo Center initiated plans to use its available 3D printers to build NIH-approved face shields in local area hospitals.

The National Institute of Health approved a design that allows the shields to be worn by healthcare workers, such as doctors and nurses, according to the Pablo Center.

Holmen said he originally did not know what to expect when pulling together the group of volunteers for the Chippewa Valley Makers.

The business did not exist until two weeks ago, when the need for face shields became essential and local individuals had the resources to help, he said.

“I organized a Zoom call and there were 21 people on this Zoom call,” Holmen said. “We met each other face-to-face — virtually — and there were no egos or posturing. We were just all there to work, to help and to collaborate. It is really encouraging to do something with a group of people who are so focused on helping.”

Mike Lee, the Pablo Center’s Workforce Development and Community Outreach manager, serves as the primary influence on the construction of the face shields, as he proposed the idea of repurposing equipment from the Pablo Center.

The Spectator reached out to Lee, but he was not available for comment.

The Pablo Center currently utilizes two Prusa MK3S printers obtained through previous funds provided to the center. These printers currently reside at Lee’s home as he develops shields on a daily basis.

Suzali said the university volunteers print out the individual visor parts to then send over to other volunteers who assemble the shield. Her specific role ensures that the university 3D printers are producing the parts in a continual stream.

“The shield takes about one to two hours to print,” Suzali said. “I come into school and make sure there is a continuous cycle of things being printed throughout the day. I am on campus most of the day, I do my (school) work and I also do that every hour or two.”

Holmen said he consistently values the safety of volunteers who are working alongside the Chippewa Valley Makers. By clarifying the precaution standards of face shield construction, it can ensure a safer product for the end user, Holmen said.

“We are assuming that everyone is a carrier COVID-19,” Holmen said. “Because the last thing you want to do when you are trying to protect medical professionals and first responders, is to get them sick. We have about 25 people that are bringing in parts periodically and we have standards for how the parts are handled and how they are packaged to minimize contamination.”

The Pablo Center Robotics Club and Eau Claire Children’s Museum are additional local businesses that have donated their own 3D printers and volunteer services towards the pandemic.

Suzali said she has been able to visualize the direct impact she and other volunteers have made towards the healthcare industry.

“A police officer actually came by and asked if we could build face shields for his department, (UW-Eau Claire) nurses also asked if we can provide masks for them,” Suzali said. “It is highly wanted and highly needed and by helping out just a little bit, it is going a long way.”

Holmen said that, as the demand for face shields continues, he is in search of smaller and local organizations — such as nursing homes and other nursing facilities — that would benefit from the resource.

“I have a feeling that there are many smaller organizations that need this that we are unaware of or don’t have contact with yet,” Holmen said. “We are trying to get as much publicity on our effort as we can so that people know it’s available, it is free and we want to get it to you.”

To request personal protective equipment from the Chippewa Valley Makers, apply here.

Suzali said despite the uncertainty caused by the pandemic, there are ways to help out others during this time, even within the isolation of your room.

“I highly encourage anyone to do whatever they can to help out, it makes you feel like you are a part of something bigger,” Suzali said. “In my case, I feel that I am.”

If you are a student who lives in the Eau Claire area and are interested in volunteering towards the production of healthcare equipment, apply here on Handshake by Friday, April 17.

Nelson can be reached at [email protected].

Evelyn Nelson is a third-year Journalism and Environment, Society and Culture student. This is her fifth semester on The Spectator. She enjoys fulfilling her dream of being a barista, at SHIFT Cyclery and Coffee Bar. Stop by for some great coffee and conversation!